INSTRUCTOR // Adam Cunningham

Adam has been working in professional metal fabrication for 10 years. He carries a wide range of skills but focuses on welding with MIG, Flux, and TIG. Adam has completed projects from Everett to Seattle building everything from art pieces to architectural structures.

Adam loves the outdoors and spends his free time exploring the Pacific Northwest.

OVERVIEW

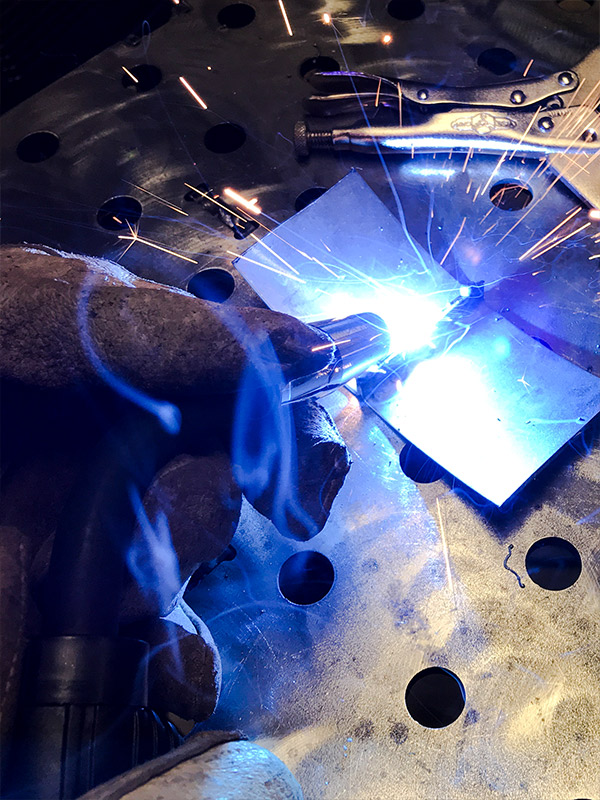

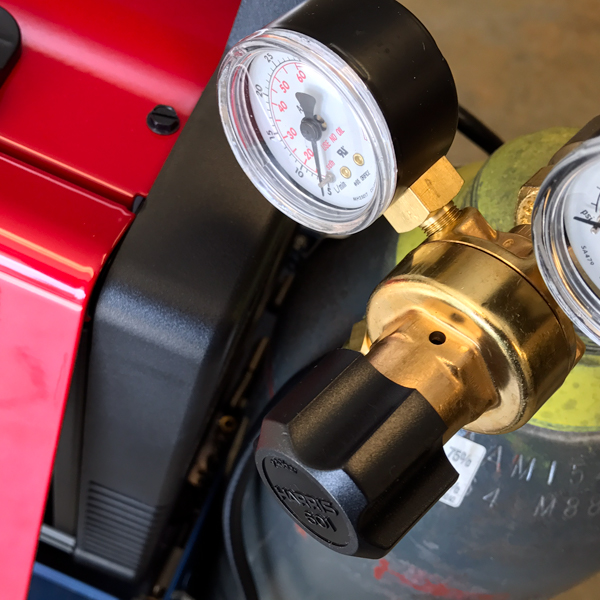

Metal Inert Gas (MIG) welding enables you to quickly and easily join mild steel parts.

MIG welding, a versatile and efficient process, has been a cornerstone of metal fabrication since its development in the 1930s. The technique’s use of a consumable wire electrode and a shielding gas allows for rapid, high-production welding. Whether you’re drawn to the speed and ease of MIG welding or the satisfaction of creating strong, durable joints, this process offers a rewarding and practical path into the world of metalworking.

Whether you are fabricating a part or creating a prototype for discussion, the ability to join metal correctly and safely is a valuable addition to your skillset. Imagine building sturdy metal furniture, repairing automotive parts, or fabricating custom metalwork for your home or garden. MIG welding opens up a wide range of possibilities for both hobbyists and professionals.

In this 2-hour class you will learn fundamental skills necessary to make strong welds in mild steel. Your instructor will explain safety concerns, describe how the equipment works, familiarize you with essential terminology, introduce you to basic joints, and demonstrate appropriate equipment operation. You will learn how to set up the equipment, prepare your material, fixture your parts, and understand what it takes to make a good weld. You will develop a working understanding of the benefits and limitations of welding so you are prepared to design with this process in mind. Your instructor will cover best practices including how to reset equipment to original conditions for the next user. Along the way you will gain the knowledge and confidence to process appropriate material safely and troubleshoot typical issues.

You will walk away with the ability to safely process appropriate metals and fabricate your own projects using our MIG welding rig.

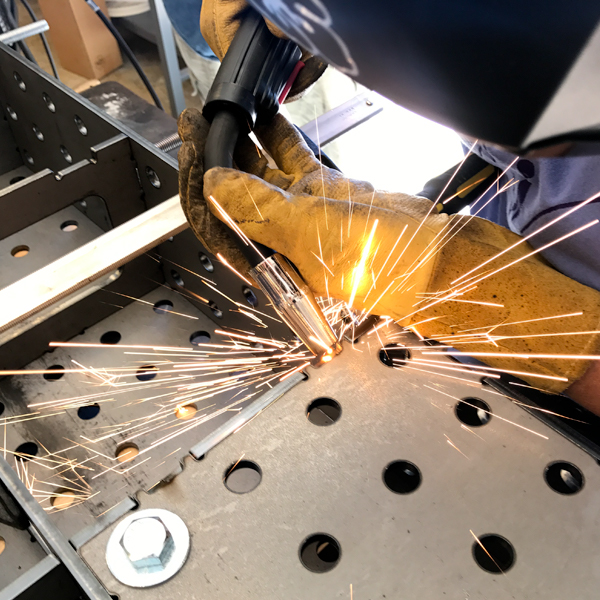

This is a hands-on training. You will have time during class to create a finished object to your instructor’s specification that demonstrates your understanding of the process and your ability to safely operate this equipment.

ACCESS

Pass this orientation and you’ll walk away with access privileges to independently operate our MIG welding rigs. This class is also a prerequisite for our Advanced Welding trainings.

HARDWARE

-Lincoln 140 MIG Welder

-Fixture Table

-Angle Grinders

-Horizontal Bandsaw

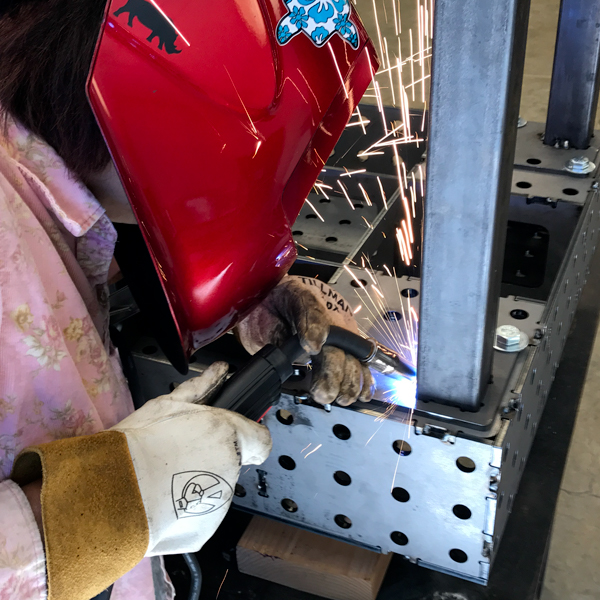

SAFETY – PLEASE WEAR

-Eye protection (safety glasses and welding helmets are available on site)

-Leather gloves

-Natural fiber clothing (long sleeves and pants)

-Non synthetic closed-toed shoes

-Stow all dangling clothing or jewelry

-Tie back long hair

NOTE

If this is your first class at The Facility please arrive 15 minutes early for a short safety briefing and some paperwork.

Orientations start promptly at 6.00p.

This Orientation prepares you to safely perform basic operations on supported equipment. It is not intended to cover design concepts or comprehensive operation of this equipment. If you are interested in learning more about design or advanced equipment operation look for additional upcoming classes.

Safety and Basic Use (SBU) Orientations at The Facility are open to anyone over 18 years old. Please feel free to pass this invitation on to others. Minimum enrollment of 3 people is required to hold the orientation.