3D Printer Orientation | FEB 13

NEXT CLASS Thursday, February 13

$50/person

This orientation clears you for independent access to our 3D Printers.

Do you have a complex CAD model you want to bring into the real world? Maybe you need to be able to rapidly iterate an idea, generate a one-off part, or produce a short product run for feedback.

Whether you’re after a form study or a functional prototype, 3D printing enables you to turn bits into atoms to create accurate physical objects from computer data.

If you want to dive into this emerging technology, our Safety and Basic Use (SBU) Orientation gets you up and running on a variety of 3D printers faster than you ever thought possible. In this 2-hour orientation you will learn the basics of how 3D printers work, how to prepare CAD models for 3D printing, and how to use our supported equipment to print your designs. You will learn the benefits and limitations of our Form 2, Ultimaker S5, and TAZ 6 printers so you understand how to pick the right equipment and how each fits into our breakthrough atoms>bits<atoms workflow.

This hands-on class focuses on equipment operation. If you are looking to pursue a deeper understanding of what 3D printers can do and where this technology is taking us, look for upcoming classes in 3D printing theory.

There are no other prerequisites for this orientation. To register, click on the next available date (highlighted in green below) and check out through the shopping cart.

INSTRUCTOR // David Voetmann

David, a lifelong designer and maker, spent his childhood in Africa. This formative experience instilled a conviction that it’s better to create your own solutions than to wait around hoping someone else will solve your problems. To this end, he earned a BFA in Industrial Design at the University of Washington. This study deepened an enduring conviction that solving problems and making things is deeply coded into our humanity. Over the last few years he has explored the transformation of our economy as new technologies begin to democratize opportunity. He now runs The Facility Makerspace where ordinary people with extraordinary ideas gain access to an 11,000sf sandbox for innovation with all the tools, training, and community people need to turn thoughts into things. He still believes that, while technology is great, we need to focus on solutions not tools.

David lives in Shoreline with his wife Ruth.

OVERVIEW

3D printing technology is transforming the way we prototype and manufacture products. Whether you are printing a quick form study, creating a complex fixture, making a mold, or outputting a final product you will be amazed by what you can accomplish with a basic understanding of 3D printing hardware and software.

Like other CNC equipment, 3D printers are disrupting many of our assumptions. The innovative way in which these machines build physical objects is altering our thinking across a wide spectrum of fields from economic theory to material science. When every product this machine produces can be completely different our assumptions of “economy of scale” are not as irrefutable as they were just 5 years ago. Meanwhile, we are seizing new opportunities to create products with previously unattainable functions like complex internal geometry. By changing the way we process materials 3D printers are challenging the way we design, expanding what we can design, and opening up brand new possibilities.

If you are interested in embracing this new way of creating our 3D Printer Orientation is a brilliant place to start. This crash course provides an engaging and fast paced introduction to 3D printing. In this 2-hour class we will help you see through the hype and leverage existing equipment with a practical approach you can use today to revolutionize the way you create. For all their near magical properties these devices are still just tools. Learn how to use them in a variety of ways across your creation workflow. We’ll cover everything you need to know from where to find existing models to the preparation of your digital model to how to operate various slicing engines, proper procedures and best practices for operating 3D printers, to methods for post processing your printed model. You will learn everything you need to know to turn the digital models on your computer into physical objects with a variety of mechanical properties.

After a short classroom overview of how 3D printing works, this orientation moves to our Rapid Proto Lab where we introduce you essential terminology and the variety of equipment available to you at The Facility. You will learn about the benefits and limitations of each piece of equipment, the materials they can use, and an overview of other options available to you through outside printing services. We will demonstrate the software that drives each printer and appropriate equipment operation. We will discuss design how to convert solid CAD models or object scans into manifold surface models that are ready to be printed.

You will get hands-on experience as you learn how to operate each of these pieces of equipment. Along the way you’ll pick up tips and tricks to get better results.

ACCESS

Pass this orientation, or a checkout, and you’ll walk away with access privileges to independently operate our supported 3D printers. This orientation is also a prerequisite for upcoming advanced 3D printer trainings.

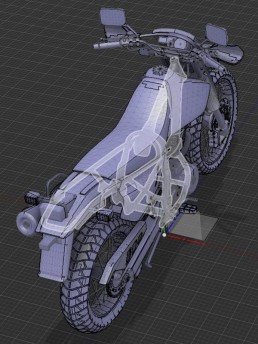

HARDWARE

-TAZ 6

-Form 2

-Ultimaker S5

SOFTWARE

-Cura for our TAZ and Ultimaker FDM printers

-PreForm for Form 2 SLA printer

NOTE

If this is your first class at The Facility please arrive 15 minutes early for a short safety briefing and some paperwork.

Orientations start promptly at 6.00p.

This Orientation prepares you to safely perform basic operations on supported equipment. It is not intended to cover design concepts or comprehensive operation of this equipment. If you are interested in learning more about design or advanced equipment operation ask about additional upcoming classes.

Safety and Basic Use (SBU) Orientations at The Facility are open to anyone over 18 years old. Please feel free to pass this invitation on to others. Minimum enrollment of 4 people is required to hold the orientation.